Introduction:

The stock stampede plastic breech does not have an air-tight bolt to barrel seal, hence the plastic bolt itself is essentially the barrel. Once the foam dart is fired out the bolt, the foam dart already starts losing power and velocity. In addition, most of the air pressure from the plunger is wasted once the foam dart leaves the bolt.

The design objective of an air-tight brass breech system is to create a 100% air-tight seal all the way from the plunger through to the barrel, thereby providing efficient air pressure delivery to propel the foam darts further.

This would result in more power within each shot, with greater firing distance and faster dart velocity.

For a Stampede brass breech to work, it requires the air-tight connection of matching brass tubes and a guide cover to ensure that all the moving parts are aligned properly.

My design is optimized to work with stefans (short length customized foam darts), although it could be adapted to use normal length foam darts, they usually wouldn't perform as accurately or consistently, and may result in much higher rates of jams.

The following guide will cover my customized version of the "Brass Breech" mod.

Credits:

My brass breech design for the Stampede is based on the excellent "PVC guide cover" design by Oxymoron at the OzNerf forum, full credit goes to him for that design.

Link to the original "Oxy's Stampede Breech" thread by Oxymoron at the OzNerf forum.

Important Note:

The "Brass Breech" mod is a more advanced mod project that should only be performed by those who are already familiar with modding the Stampede.

For new modders, please refer to my Nerf Stampede Mod Guide to get familiar with the modding basics first.

Disclaimer: Modify at your own risk. Modifications may wear out or damage your blaster. Please be careful when using hobby tools!

Lets start...

Step 1: You will need to obtain 3 different sizes of brass tubes (Brand: K&S Engineering) and a suitable PVC pipe for nesting them into.

The brass tube sizes are: 1/2", 17/32" and 9/16". All of them are 0.014" wall thickness. They are usually supplied at hobby shops in either 1 ft or 3 ft length tubes.

I use a 13mm SingaPlastics brand PVC pipe which can nest the 9/16" brass tube. This pipe will be used to create the PVC guide cover.

Note that the inner diameters (ID) of PVC pipes often tend to have variations, even within the same length of pipe, so you have to test different sections and make sure it fits the brass tubes before usage.

Its recommended to prepare and polish the brass tubes with some metal polish to remove any oxidization that may have occurred both externally and inside the tubes, this helps smoothen out the surfaces for lower friction and better fit.

As you can see, the brass tubes nest perfectly within each other and they all form an instant 100% air-tight seal. Those who have worked with brass breech systems will be very familiar with this unique characteristic. :)

Step 2:

Lets start with the PVC guide cover, this is the most essential part of the Stampede brass breech system. The guide cover ensures that the moving brass bolt chambers each foam dart into the barrel properly and consistently.

Take the PVC pipe and mount the N-Strike clip on it.

Use a marker to trace the outline of the clip's shape.

Use a Dremel with cut-off wheel to cut out the traced lines.

As the top section of the guide cover ends up being a rather thin strip of PVC (which will tend to flex too much), i cut out another shaped part from a larger 16mm SingaPlastics brand PVC pipe which is then glued on the top to further reinforce and stiffen that section.

The PVC guide cover is done!

Step 3:

Now we proceed on to the brass barrel section.

In my example, i use a 21 cm length (8+ inch) of 9/16" brass tube as the barrel. It is nested and glued into the PVC guide cover.

Use a Dremel with sanding bit to bevel the inner edges of the brass barrel, this creates a funnel design to enable smoother chambering of the foam darts and brass bolt.

I positioned the barrel and guide cover assembly to align with the internal dimensions of the Stampede, an additional PVC pipe was nested at the front of the barrel to help keep it in line with the Stampede's front casing structure piece.

The orange collar piece is also positioned and glued to the PVC guide cover to establish a fixed securing point to the blaster casing.

The brass barrel section is done!

Step 4:

Next we proceed to the brass bolt section.

Use a pipe cutter to cut away the stock plastic bolt, as shown in this photo.

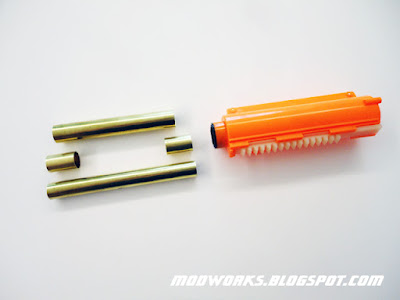

To make the brass bolt parts, use a Dremel to separately cut out a set of brass tube sections in the following lengths:

1/2" brass tube: 11 cm

17/32" brass tube: 2 cm (2 x spacer sections)

9/16" brass tube : 9 cm

These are my custom tube measurements for the Stampede brass breech system.

These measurements need to be as accurate as possible. Any variations may affect the overall structure and air seal of the breech system.

Used a Dremel with sanding bit to bevel the outer edges of the brass bolt front section, this will help to further enable smoother chambering of the foam darts and brass bolt into the brass barrel.

Here is my Nested Brass Tubes Cut-Away Diagram:

Nest the assembled brass bolt into the plunger casing.

Use the strongest glue you can get to glue everything together. I use "Selleys Super Strength" 2-part slow-curing epoxy glue (curing time of 3 days!). Make sure the glue cures completely for maximum bond strength.

Note that the 1/2" brass tube acts as the air channel and helps to reduce dead space, but not too much to create an air restriction.

The 17/32" brass tube will chamber the foam dart and connect into the 9/16" brass barrel, this is what creates the 100% air seal.

The brass bolt section is done!

Step 5:

Sleeve the brass bolt into the PVC guide cover. Test the parts movement and connection with the brass barrel.

The brass bolt must be able to move smoothly within the PVC guide cover without resistance.

If there is resistance, use a Dremel with sanding bit to widen the inner diameter (ID) of the PVC guide cover until it fits.

When the 17/32" brass bolt connects into the 9/16" brass barrel, it should have a 100% air-tight seal. Test the seal by closing the breech, then manually compressing the plunger while blocking the barrel exit, there should be resistance felt in the plunger rod.

Next, install all the parts into the Stampede.

Test the parts fit and test the movement of the brass bolt. Make sure everything moves smoothly.

If there are parts which encounter resistance, either loosen or trim the fit and test again.

Assemble everything together, keep testing the movement of the parts as you assemble the blaster.

Its completed!

Here are some close-ups of the breech system:

Awesome!

Stampede Brass Breech - Demo & Test Fire Video:

Sample Test Fire Results:

PTG: Parallel-To-Ground (Shoulder height, no elevation)

ATG: Angled-To-Ground (Aimed higher, 30 degrees elevation)

Distance is measured at where the dart lands (Average of 6 darts).

Brass Breech Stampede (9kg Load Spring)

Ammo: Customized FBR foam + 1.1 gram soft silicone tip weight

PTG = 95-105 ft

ATG = 120-130 ft

Note that the test was done indoors with customized foam darts and the results are sample estimates for reference (your results may differ depending on materials and mod techniques used).

Important User Tips:

- Short length customized stefans work best with this breech system, make sure that the stefans used are in perfect condition and fit the brass barrel properly (not too narrow or not too wide). In addition, ensure that the back portions of the stefans are rounded without any excess foam sticking out which might get clipped by the brass breech when it closes. Taking care of these various factors will greatly reduce the chances of jamming.

- With the clip and trigger locks removed, do not put your fingers into the breech section when the blaster is in operation, as this can result in injuries.

- The better the foam dart fit in the brass barrel, the better the range results.

Variants:

For fans of minimized Stampedes... check out the brass breech mod done on my "SMG" Variant!

Note the extra length of PVC pipe and coupler covering the brass barrel in front, it is designed to cover the brass tube edges for safety in Nerf games. :)

Check it out in action!