Mods covered:

- Air Restrictor (AR) Removal

- Plunger Padding

- Spring Replacement

Note: These mods are also applicable to the Nerf Recon as it shares similar internal mechanisms as the Nerf Raider (some of the info here may also be repeated at the Nerf Recon Mod Guide).

>> Nerf Recon Mod Guide

>> Nerf Longshot Mod Guide

Disclaimer: Modify at your own risk. Modifications may wear out or damage your blaster. Please be careful when using hobby tools!

:: AR Removal ::

Step 1: Disassemble your Raider. Make sure to remove all the screws before detaching the casing. There are 14 screws in the main body, 5 screws in the front grip and 2 larger screws in the grey plunger cap.

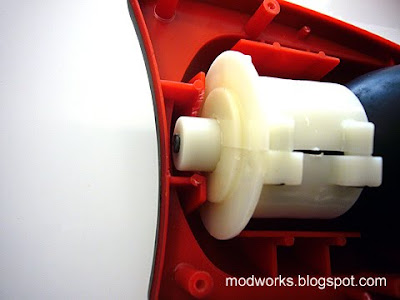

Step 2: Detach the bolt, plunger and bolt sled. Unscrew the top plunger guide rail for easier access.

Step 3: Knock out the metal retaining pin that holds the bolt and bolt sled, this will separate the bolt from the bolt sled.

Step 4: This is the "Pipe Cutter" method. You will need a rotational pipe cutter to cut the bolt in order to remove the AR.

Please observe closely the spot where the pipe cutter blade is positioned at. That is the correct position to cut (though you can deviate 1mm either way). Just tighten the pipe cutter slightly and do the rotational cut (not too much or else it might slice the bolt in half).

In the following photo, a pre-sliced cut has already been made for reference.

Rotate the pipe cutter 2-3 times, and try to pull apart the bolt. If it doesn't move, rotate the pipe cutter again, do not over-tighten the pipe cutter! Keep testing. Very soon, the bolt will separate into two parts and the AR will just drop out.

Step 5: Join back the 2 sections of the bolt sleeve using plastic hobby or epoxy glue. Let the glue set properly before re-installing back into the blaster.

Before AR removal (top photo) & After AR removal (bottom photo).

:: Plunger Padding ::

Without the AR, there is no air buffering system to cushion the plunger on bolt impact.

This results in very high wear and tear on the plunger, by both normal firing and dry firing. Due to repeated direct impact on the bolt (hence the loud cracking sound during firing), many users of modded Raiders have experienced bolts eventually punching a hole out of the back of the plungers!

Therefore, padding should be applied to the plunger to help cushion the impact.

In the following photo, soft rubber padding is attached to the base of the plunger.

The 20mm diameter soft rubber pads i used in the above example are from a brand called "Volkmar-Fix", they can be found at most common hardware shops.

Make sure to only use soft rubber pads that are easy to compress, so that it can allow the bolt to move backwards fully for proper loading/unloading of magazines and chambering of darts.

Experiment with various plunger padding methods to help maintain the durability of AR removed blasters over long-term usage.

:: Spring Replacement ::

One way to increase the speed of air delivery through the bolt is to replace the stock spring with a stronger aftermarket spring.

There are many different springs with different sizes and spring force ratings. Springs can be sourced from your local spring supply shops. Spring choice will depend on your usage.

This example below shows a stock spring (top photo) vs. an aftermarket 6kg load spring (bottom photo).

Stronger springs are usually made of thicker wires. Internal casing trimming and adjustments may need to be done so that the springs have enough space to expand when compressed, for smooth firing operation.

Stock internal casing (left photo) vs. Trimmed internal casing (right photo).

Depending on the strength of the spring used, extra catch springs may also need to be added to hold the increased tension.

Note that a stronger spring will require more effort to prime the blaster before each shot, and the impact of the plunger on the bolt and overall stress on the blaster casing is also much greater. It'll be important to account for these factors when doing a spring replacement.

:: Sample Test Fire Data ::

PTG: Parallel-To-Ground (Shoulder height, no elevation)

ATG: Angled-To-Ground (Aimed higher, 30 degrees elevation)

Distance is measured at where the dart lands (Average of 6 darts).

Stock Raider

PTG = 20 ft

ATG = 30 ft

Modded Raider (AR Removal & 6kg Load Aftermarket Spring)

PTG = 50 ft

ATG = 60 ft

Note that the test was done indoors with customized foam darts. The results are sample estimates for reference (your results may differ depending on materials and mod techniques used).