Personally, i have no dedicated workshop space to do my hobby modding work (unlike those lucky chaps who have actual garages or workshops to work in), so my modding is usually done either at my dining or study table and both locations are not conducive for all the cutting and drilling work (and my neighbors are not keen on people drilling stuff at the apartment corridor either).

Add in the noise from the motorized tools, along with all the remaining dust particles and sharp bits lying around that end up in everyone's food or clothes for the next few days, overall not ideal environments to work in.

So i had an idea...

Make a Portable Modding "Clean Lab"!

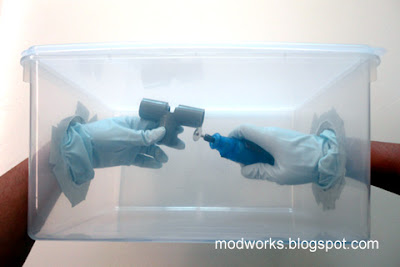

And this is what i made in less than 10 minutes:

It works like a charm! All the dust particles and fumes stay inside the plastic box, it is portable so i can do my modding work anywhere at home (or at the office!) and all the mess is contained. After everything is done just tip out all the dust particles in the trash.

And because the entire box is sealed, even the sound of the motorized tools operating within it is muted! No more complains from family members or colleagues about anymore noisy cutting and drilling. :)

Here are some tips on how i made it with some simple household items...

Step 1: Get a suitable sized transparent plastic box (the plastic material should be as clear as possible) and then simply cut 2 holes on each side.

Step 2: Get a pair of rubber washing gloves, and simply attach them into the cut-out holes. In my example, i just used duct tape (alot of it) to secure the gloves to the plastic box holes, make sure there it is fully sealed so no dust can escape.

Step 3: Test it out... nice!

Its done! Here is to a much neater modding experience! :)

That's truly the most clichéd awesomnest thing I've seen in a verrrry long time. Brilliant idea.

ReplyDeleteKeith,

ReplyDeleteYeah, i have wierd allergies so even when i wear a dust mask during the cutting and drilling work, i'll somehow still keep sneezing the rest of the day... thats why i made this dust retention system, so that i can mod without all the discomfort and mess.

Clear plexiglass or polycarbonate boxes would be suitable too, i was originally going to build it out of those materials, but decided to just convert a simple transparent plastic box 'cos it was quicker and easier. :)

That's a cool device you've made there, SG Nerf. What are you working on in the picture?

ReplyDeletenot to repeat the others but this is genius. great solution to both my asthma and the mess. just a couple of questions: 1. How do u clean the dust inside of it when ur done? 2. Do u think an oversized tuppleware box (the ones with the removavble lid) be a good alternative for a plastic box?

ReplyDeleteErik,

ReplyDeleteIn the photo, i was working on parts for this:

http://diyblasters.blogspot.com/2010/11/sgn-r-series-blasters-r3l-review.html

Cutting and drilling PVC is really dusty work. :)

djcasio,

ReplyDeleteTo clean the box, i simply open the lid and tip all the dust out into a trash bin outside.

The plastic box i used is actually kinda like a large Tupperware box, you'll just have to find versions made of clear plastic.

wow. thats actually a really good idea! i'm impressed.

ReplyDeletealso, does that piece in the example photo mean we'll be seeing another iteration of your catch ring design?

Jeff,

ReplyDeleteYup, i'm constantly developing and testing new blaster designs and variants, so i'm always making new parts for them. :)

Wow, just Wow! I can't believe I never thought of something like this. I can't tell you how tired I am of cleaning up after a mod. This is genius. I'm going to make one right now. I owe you big time.

ReplyDeletewhat if your dremel has a cord. do you just add a hole for the cord.

ReplyDeletejerm781,

ReplyDeleteThanks! Yeah, its a useful system for modders and blaster builders, makes working on projects alot more comfortable. :)

lucia_tom,

ReplyDeleteCorded Dremel? Well, then as you mentioned, a hole would need to be made to thread the power cord through.

I guess the sealed box system is designed to work best with cordless tools. :)

How about if ur using a AC powered dremel

ReplyDeleteBlogger,

ReplyDeleteAs mentioned in my previous comment, you'll probably have to somehow thread the power cord through a hole in the box.

Imho, cordless tools work best with such sealed container systems, maybe you should consider getting a cordless dremel instead. :)

Such an amazing idea! I really need to make one of these. Is it hard to see inside? Also, does the container have a clear lid?

ReplyDeleteBednesti,

ReplyDeleteWell, the entire plastic box (including the lid) i use is transparent enough that i can see everything inside it clearly.

If you are using corded tools, you could always drill a hole in the container, put the cord through, and then use a removable putty (IE sticky tack) to seal the hole so that fumes don't escape.

ReplyDelete